Last-Mile Vaccine Carrier (2023)

Carousel Design for ManufacturingFor: MIT DLab Design for Scale

Client: IDEABATIC

Project by: Kevin Tang, Kaili Glasser, Shua Cho, Yutong Zhang

Introduction

The focus of this project is to redesign the existing SMILE carousel to be injection moldable in order to reduce cost at volume. We are able to design the carousel to require only 2 injection molds and 1 die cut mold while maintaining its core thermal, structural, and usability performances. The next step is to evaluate further the exact tolerances for injection molding and its integration with the SMILE housing.

The focus of this project is to redesign the existing SMILE carousel to be injection moldable in order to reduce cost at volume. We are able to design the carousel to require only 2 injection molds and 1 die cut mold while maintaining its core thermal, structural, and usability performances. The next step is to evaluate further the exact tolerances for injection molding and its integration with the SMILE housing.

Problem Background

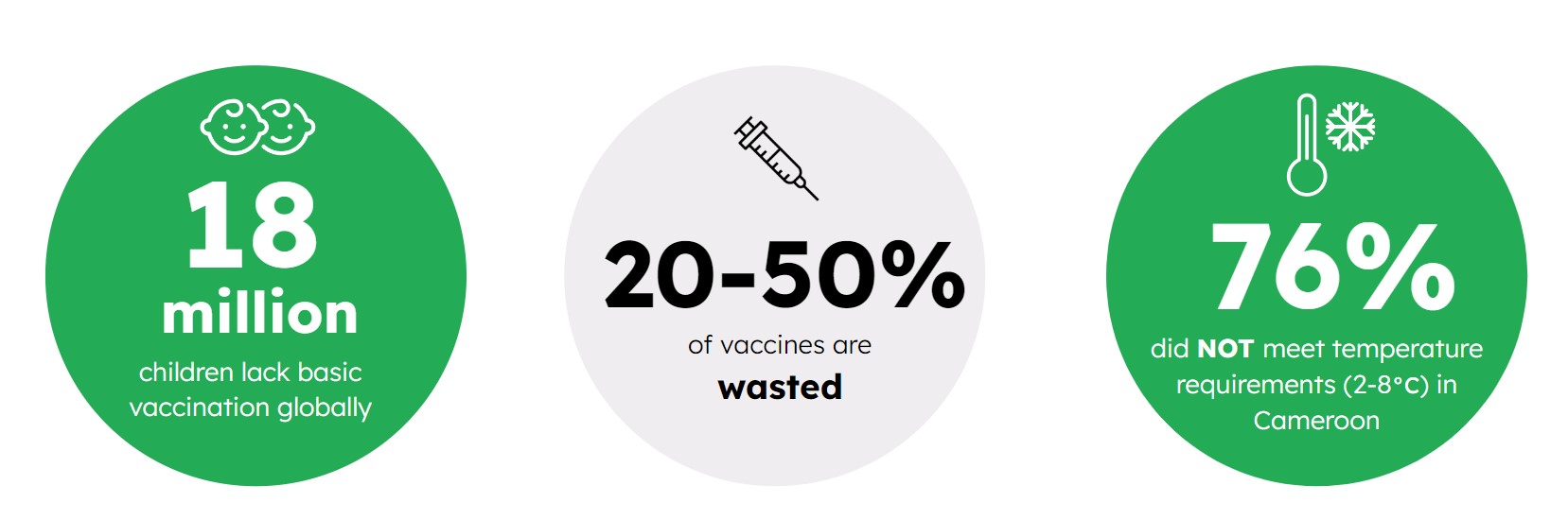

Vaccine Last-Mile Cold Chain Inadequacy

In the realm of vaccine delivery, the "last mile" remains a critical challenge, often overshadowed by the significant funding disparities compared to vaccine creation. Current cold-chain equipment struggles during this final leg, leading to freezing vaccines or failing to maintain the required temperature. Human errors compound the issue, accelerating vaccine spoilage. Notably, according to a study conducted by our project partner Kitty Liao in 2022, 76% of cold-chain equipment vaccine deliveries in Cameroon did not meet the WHO's temperature requirements (2-8 degrees C, 35.6-46.4 degrees F).

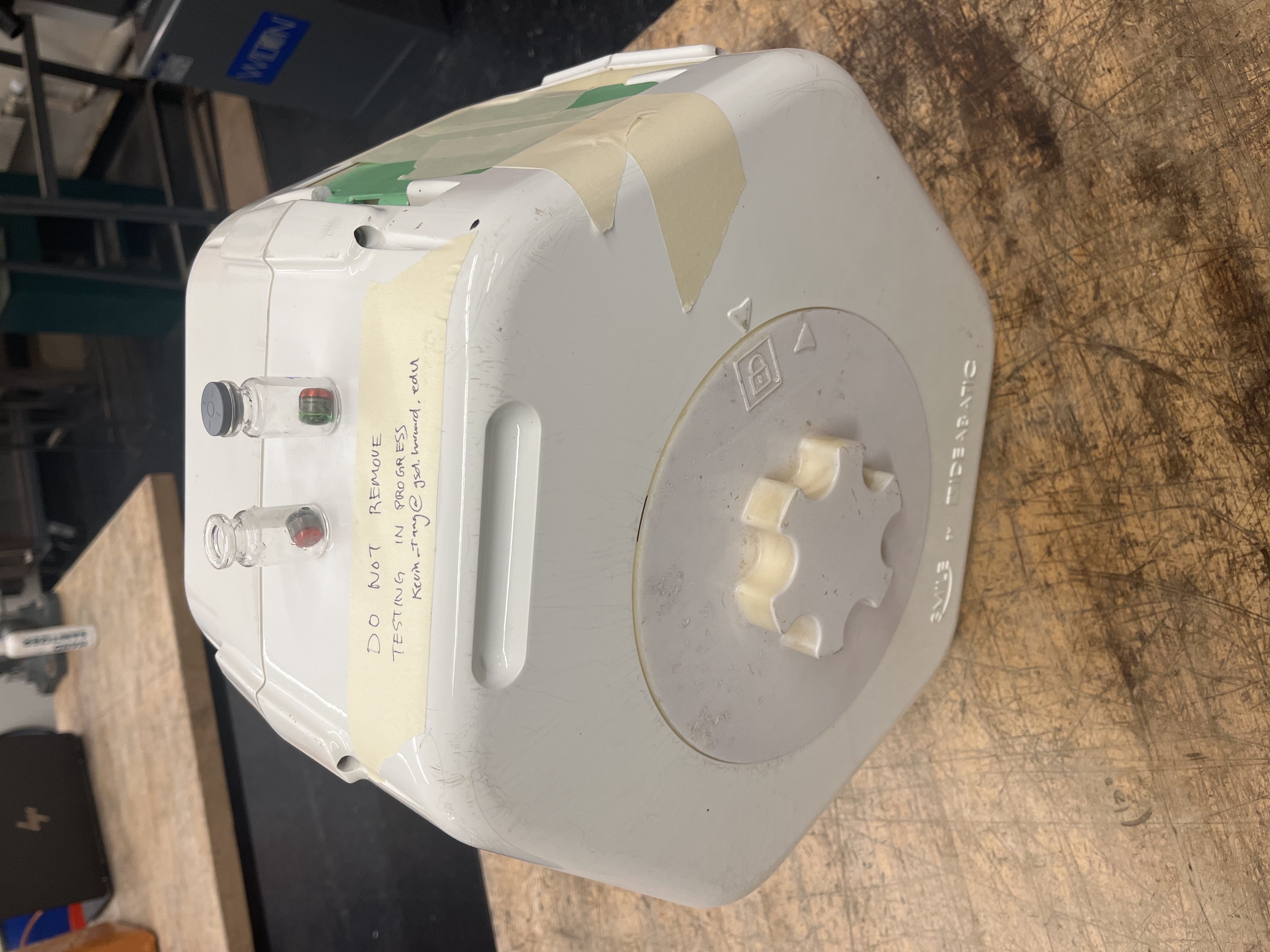

In response to these challenges, IDEABATIC, under the leadership of Kitty Liao, developed SMILE (SMart last-mILE vaccine cooling system). This innovative device is a transportable insulated spinning carousel cold-box, offering enhanced functionalities by securing, isolating, and organizing vaccines during transportation.

Team Goals and Problem Statement

The overarching goal is clear: to make SMILE a more cost-effective vaccine cold-chain delivery device in order for it to be a financially viable solution for widespread deployment. This involves redesigning the carousel and vaccine holders for injection molding and die-cutting while maintaining structural and thermal integrity. The main objective is ambitious - a 50% reduction in manufacturing costs compared to the current price. The ensuing report will delve into the details of our team's goals, progress, and the methodology employed, using CAD modeling, prototyping, and testing analysis.

Design Decisions

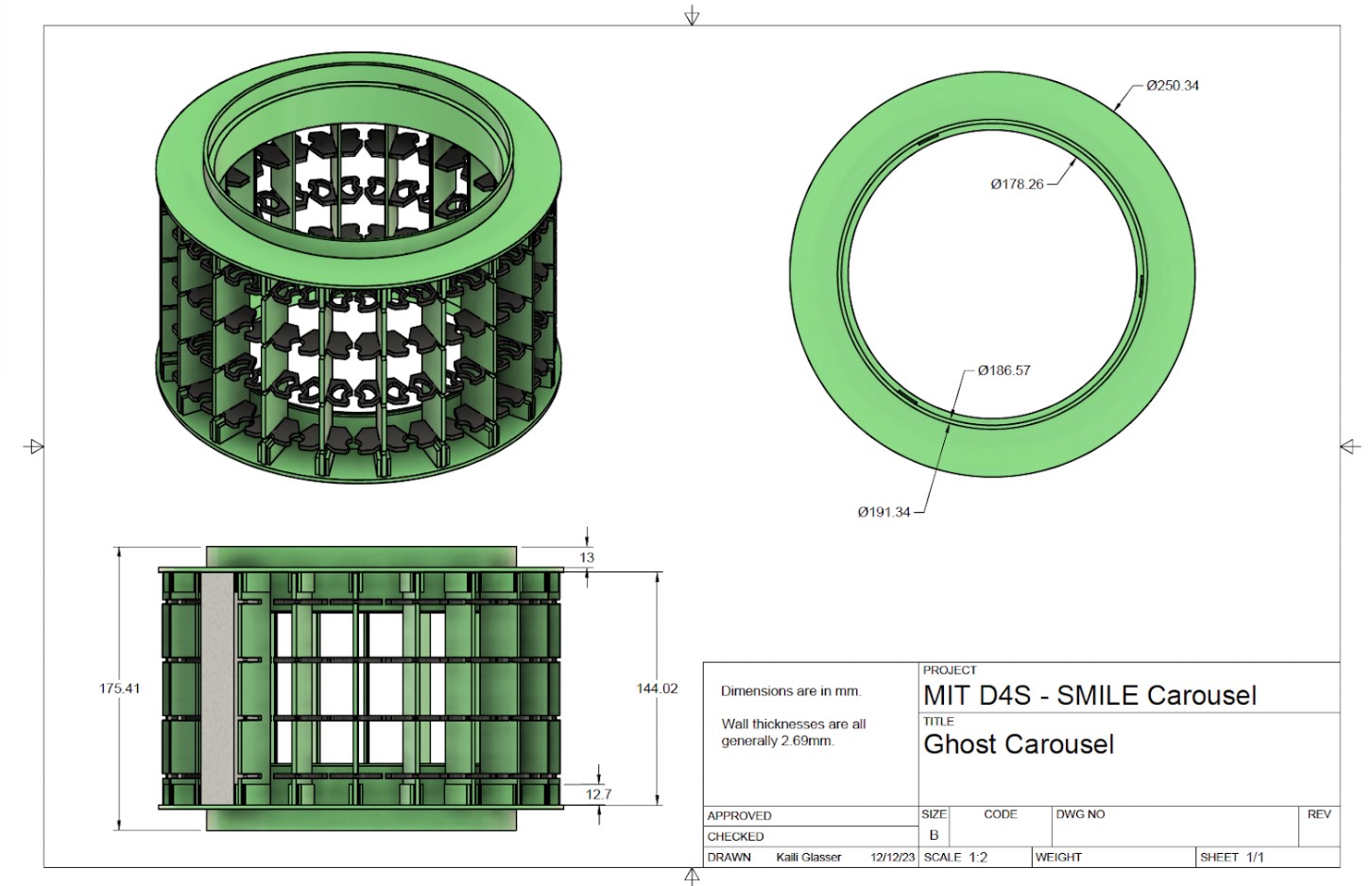

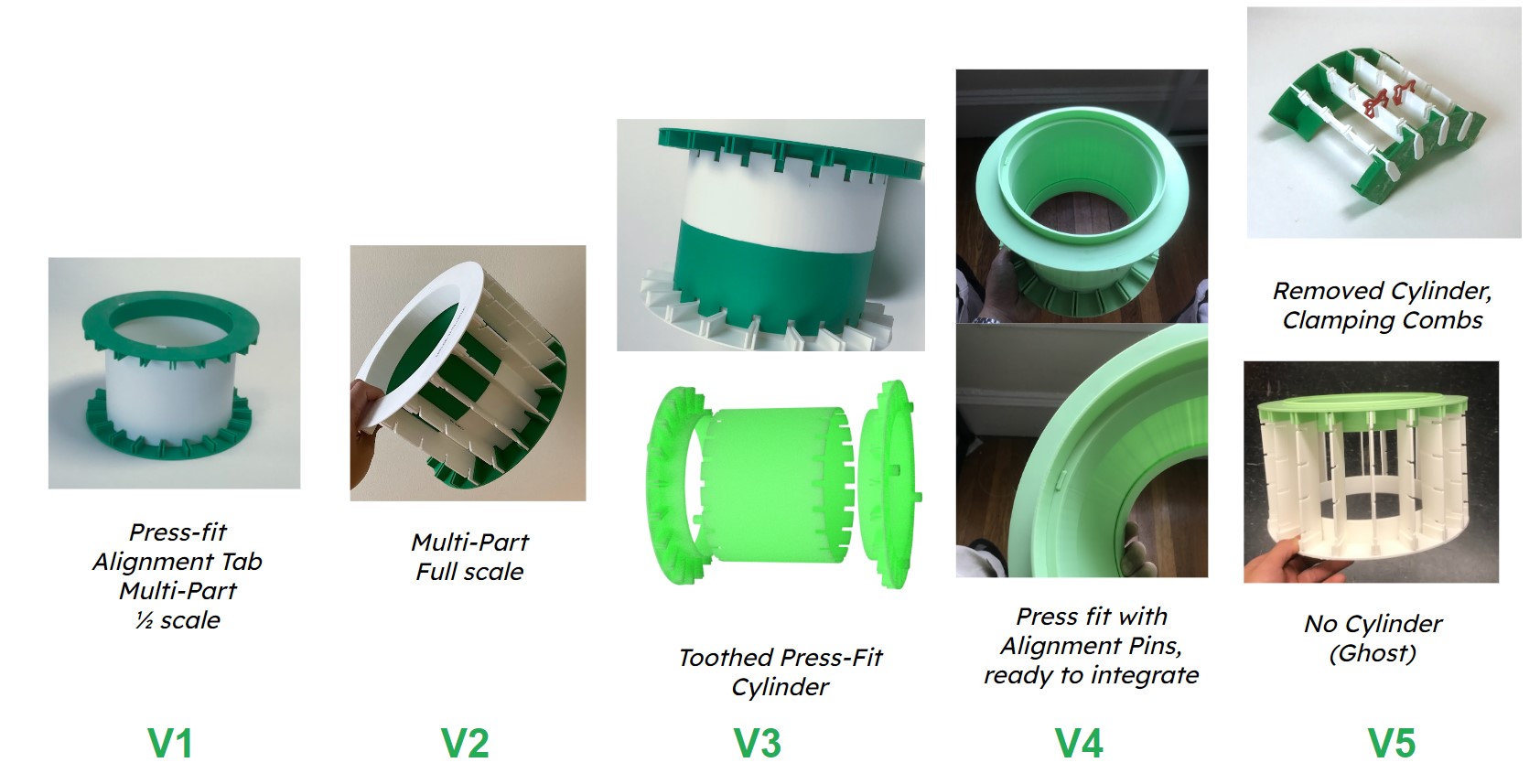

| 1. Ghost Carousel Top/Bottom |

| (Injection Molding) |

We split Kitty’s carousel into symmetric, injection moldable pieces in order to minimize the number of unique molds required. We moved the grooves that hold the vaccine holders from the cylinder to the top/bottom as the original radial extrusions were not easily injection moldable with a simple top/bottom mold. We also removed the cylinder part in the center to minimize weight without sacrificing function.

We split Kitty’s carousel into symmetric, injection moldable pieces in order to minimize the number of unique molds required. We moved the grooves that hold the vaccine holders from the cylinder to the top/bottom as the original radial extrusions were not easily injection moldable with a simple top/bottom mold. We also removed the cylinder part in the center to minimize weight without sacrificing function.

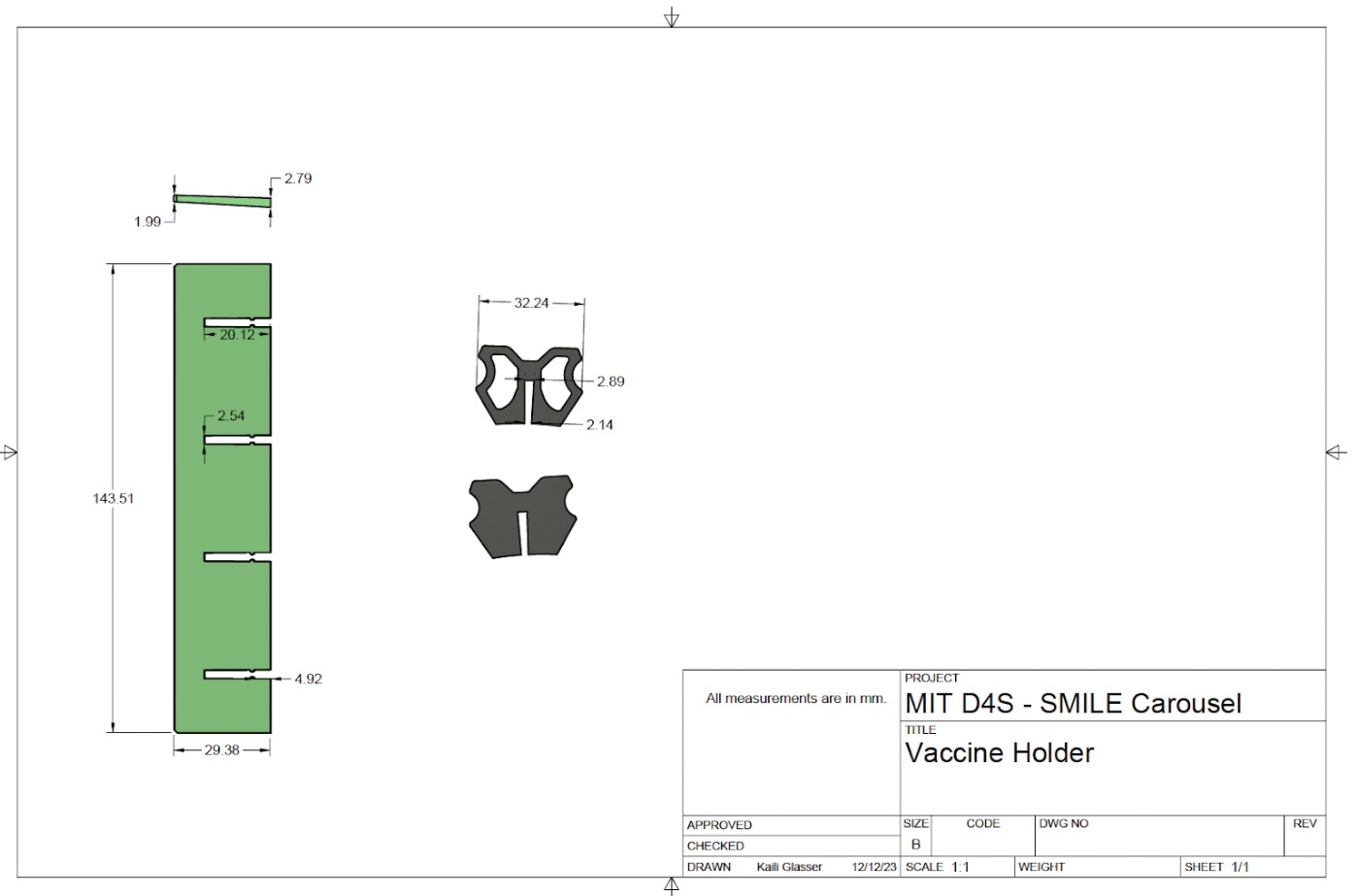

2. Butterflies

![]()

We separated the “butterfly” and comb parts to allow the butterfly parts to be manufactured through die cutting, which is a much cheaper process to implement. We used Kitty’s original butterfly geometries because they have already been proven to work well by Kitty herself.

| (Die Cutting) |

We separated the “butterfly” and comb parts to allow the butterfly parts to be manufactured through die cutting, which is a much cheaper process to implement. We used Kitty’s original butterfly geometries because they have already been proven to work well by Kitty herself.

3. Combs

![]() We added small bumps to the inside of the grooves on each comb in order to securely hold the butterfly pieces while still allowing for easy insertion/removal.

We added small bumps to the inside of the grooves on each comb in order to securely hold the butterfly pieces while still allowing for easy insertion/removal.

| (Injection Molding) |

We added small bumps to the inside of the grooves on each comb in order to securely hold the butterfly pieces while still allowing for easy insertion/removal.

We added small bumps to the inside of the grooves on each comb in order to securely hold the butterfly pieces while still allowing for easy insertion/removal.

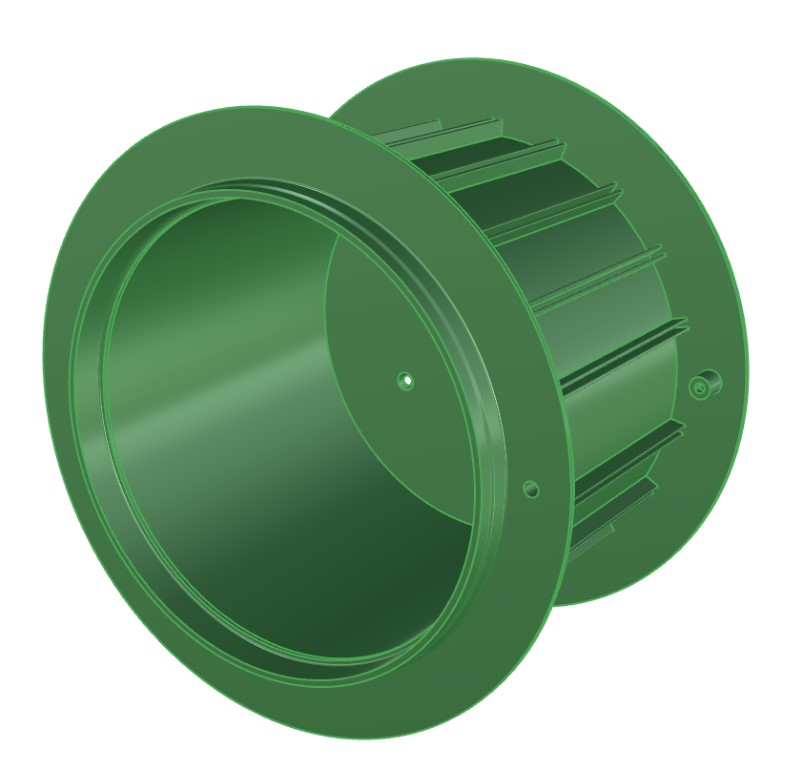

Original Design

![]()

Final Design

![]()

Manufacturing and Materials Considerations

For the vaccine carrier body, injection molding with ABS plastic is the preferred method due to its exceptional temperature resistance. ABS plastic ensures structural integrity and thermal insulation, critical for vaccine storage. The vaccine holder employs silicone sheets for their rigidity and optimal friction coefficient, which guarantee the secure housing of vaccine vials while enabling ease of insertion and removal. The use of die cutting for larger-scale production provides cost-efficiency advantages, notably reducing setup costs and enhancing mass production efficiency.

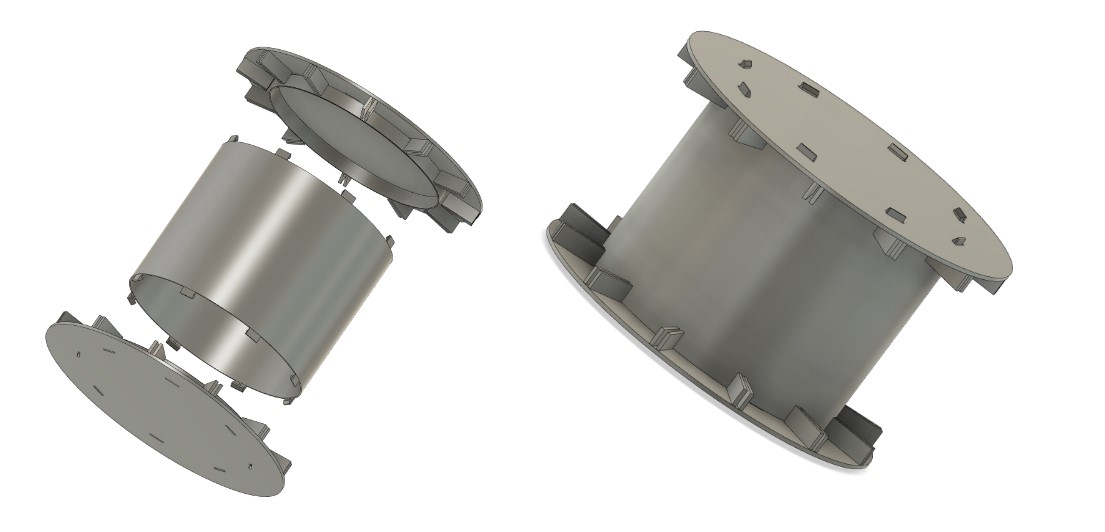

Final Ghost Carousel Design

The optimized ghost carousel achieves a 20% weight reduction through our strategic redesign of the carousel parts. The manufacturing mold breakdown includes injection molds for carousel lids and combs, a die-cutting mold for butterflies, and injection molding mold or extrusion process for the optional cylinder. This approach ensures an efficient and cost-effective production process while meeting the structural requirements of the carousel.

FMEA Analysis

| Failure Modes | Causes | Possible Solutions |

|---|---|---|

| Vaccine’s temperature is too high or too low | Heat leak from the gap or carousel being too close to the ice pack | Perform thermal test in a longer period |

| Combs slide out from carousel | Not enough friction between combs and carousel |

Perform structural test Optimize the dimension of combs and carousel gaps Press fit between carousel lids and housing |

| Carousel can’t be rotated easily | Large friction between carousel and housing or carousel is too heavy |

Perform usability test Explore other options of carousel turning |

| Butterflies not properly attached to comb | Not enough friction between combs and butterflies or material fatigue after cyclic loading |

Improve locking design of butterflies Perform usability test |

Design Process

Carousel Iterations

Comb Iterations

Butterfly Iterations

Final Carousel Assemble

In the assembly of the final carousel, our focus is on the ghost carousel design, a pivotal element of the SMILE project. The connection between the top and bottom components relies on press fits of the combs. This assembly method, while efficient, demands precision to avoid potential failure points. If the press fit isn't tight enough, twisting and disassembly may occur, impacting the carousel's rotation and function. This could jeopardize the correct alignment of combs, affecting the compression needed from the butterflies to secure vaccine vials. As we strive for a cost-effective and reliable assembly, attention to detail in press fit tolerances is crucial.

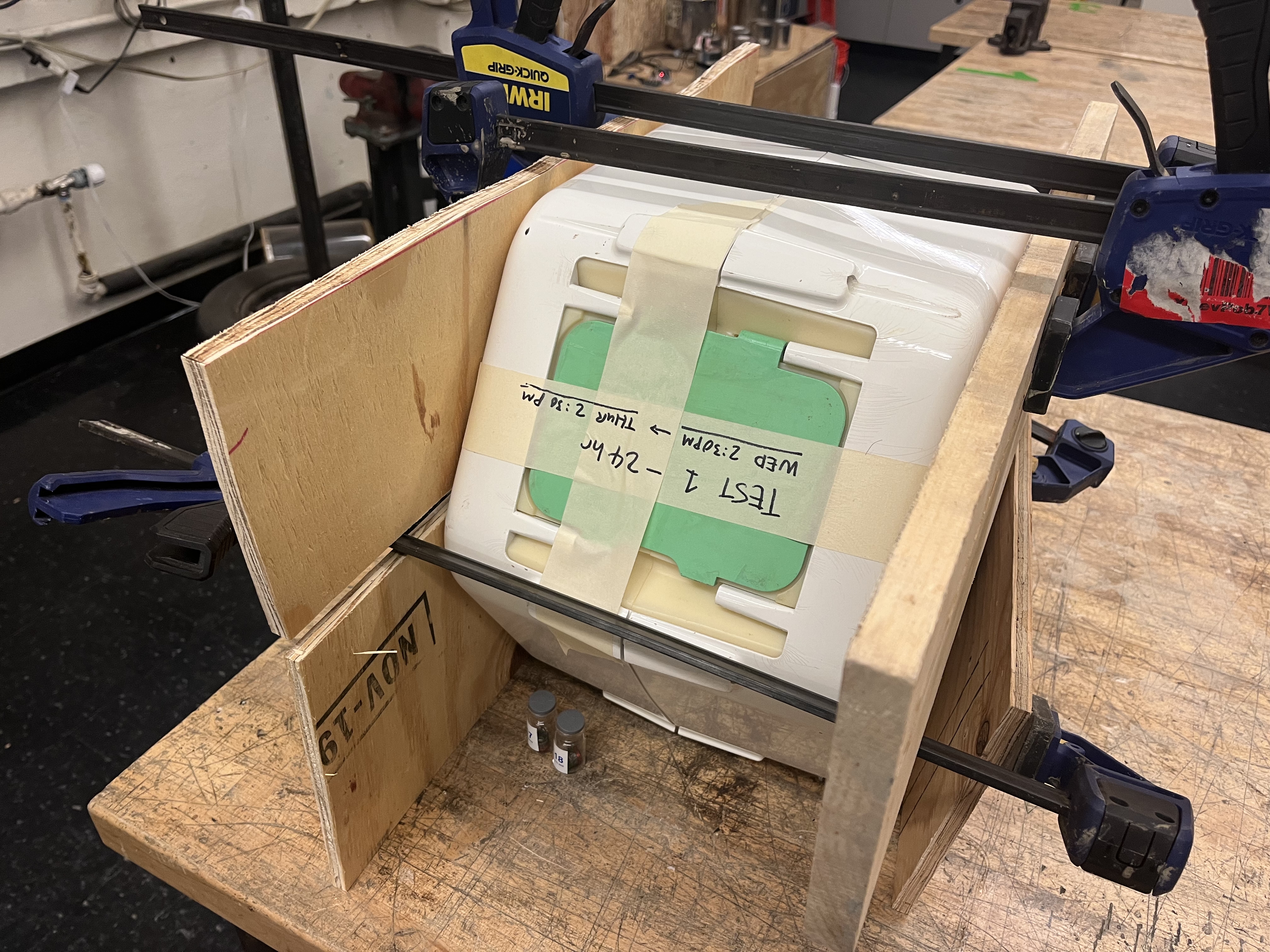

Thermal Testing Results

In order to test whether the new carousel design is able to keep the temperature of the vaccine in the range of 2-8°C, we conducted two thermal tests with the original carousel and our carousel design. We tried to measure the temperature in eight different positions on the carousel and the ambient temperature.

Engineering Drawings

![]()

![]()